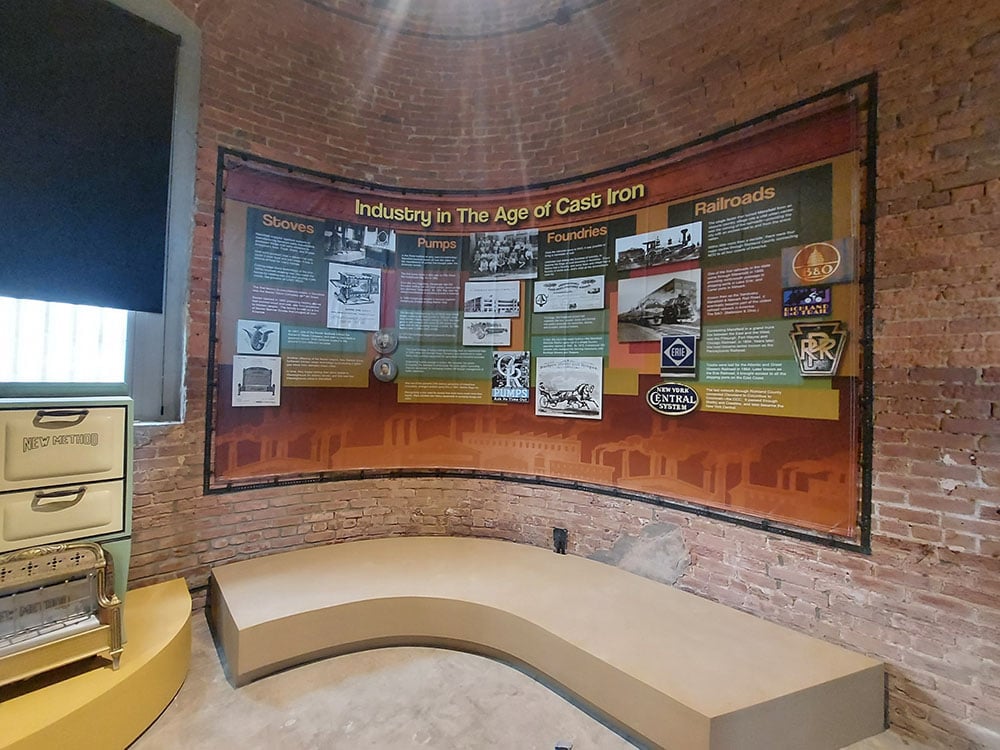

Curved Sign

The ultimate curved sign solution for surfaces where a flat track isn't feasible, BannerFrameFLEX is engineered with pre-measured sections that ensure a tight, wrinkle-free installation. Designed to prevent sagging, tracks, or rips, BannerFrameFLEX delivers a clean, professional look even on non-flat displays.

Product Details

Curved surfaces can be a challenge for even the most experienced banner installers. But with BannerFrameFLEX, you can say goodbye to wrinkles and sagging! No matter where you consider placing them, a curved banner like this accounts for every challenge that may come up. The material is designed to wrap around unconventional surfaces without loosening, regardless of whether it’s indoors or outdoors.

Using our patented spring/hook technology, BannerFrameFLEX securely fastens the banner to the frame, providing continuous, even tension across the graphic. This ensures a tight, wrinkle-free, sag-free installation every time.

Installation is quick and easy in three simple steps:

- Remove the pre-measured sections

- Secure the sections onto the surface

- Install the banner by pulling the pre-cut holes through the SingSpring ends

Traditional flat signs commonly leave gaps between the wall and the banner. They might also require intrusive methods to install, which can damage the surface or sign. With BannerFrameFLEX, there’s no need for grommets, rods, cables, or any additional hardware that could potentially affect your banner. The minimal protrusions also help extend the lifespan of your vinyl and mesh banners.

Our curved sign options are available in different sizes to fit the location where you need them. We’ve had success installing them onto brick surfaces, water towers, and silos. We also offer support for a successful installation process.

Your search ends here. Engineered for durability in extreme conditions, BannerFrameFLEX keeps your fabric graphics looking sharp from day one to the last, making it the ultimate solution for curved surfaces. Don’t let a curved surface prevent you from displaying your sign loud and proud!

SignSpring is the best fabric graphic

installation system on earth!

Yes! BannerFrameFLEX is a highly versatile solution that performs well across a variety of surfaces. Whether you're working with expansive wallscapes or smaller point-of-purchase (POP) displays, BannerFrameFLEX can be securely mounted on surfaces like brick, concrete, wood, corrugated metal, stucco, and window frames.

BannerFrameFLEX is designed for a hassle-free, direct-from-box installation. There’s no complicated setup or prep work required. Simply unpack the pre-measured sections, grab a few basic tools (like a cordless drill, attachment hardware, level, and tape measure), and you're ready to install. The intuitive process ensures a quick, secure mount on any surface, whether it’s brick, wood, stucco, or metal.

Plus, our 24/7 support team is available to provide assistance and ensure your installation goes smoothly, whether you’re a first-time user or a seasoned professional.

BannerFrameFLEX is compatible with all types of vinyl. For optimal performance, we recommend using a lighter-weight vinyl (such as 7 oz.) for a smooth, tight fit that enhances the overall appearance of your sign. For larger installations (over 100 sq ft), especially with BannerFrameFLEX, mesh vinyl is ideal. The mesh allows for proper airflow, reducing wind damage and increasing durability for larger outdoor displays.

There are no special printing requirements, but we recommend printing a 3/4" dashed line along the inside perimeter of the vinyl to guide the placement of the SignSprings. While a double-stitched hem is ideal, any finishing method (or even unfinished edges) will work with the system. To ensure a perfect fit, spec sheets are provided with each order, so you can be sure your banners are sized precisely for your BannerFrameFLEX system.

Step 1

Mark the banner perimeter on the surface of the installation site.

Step 2

Tacweld BannerFrame Flex’s base channel 1.5” off the perimeter.

Step 3

Install the banner onto the base channel by pulling it through the BannerSpring tips ¾” into the banner perimeter.